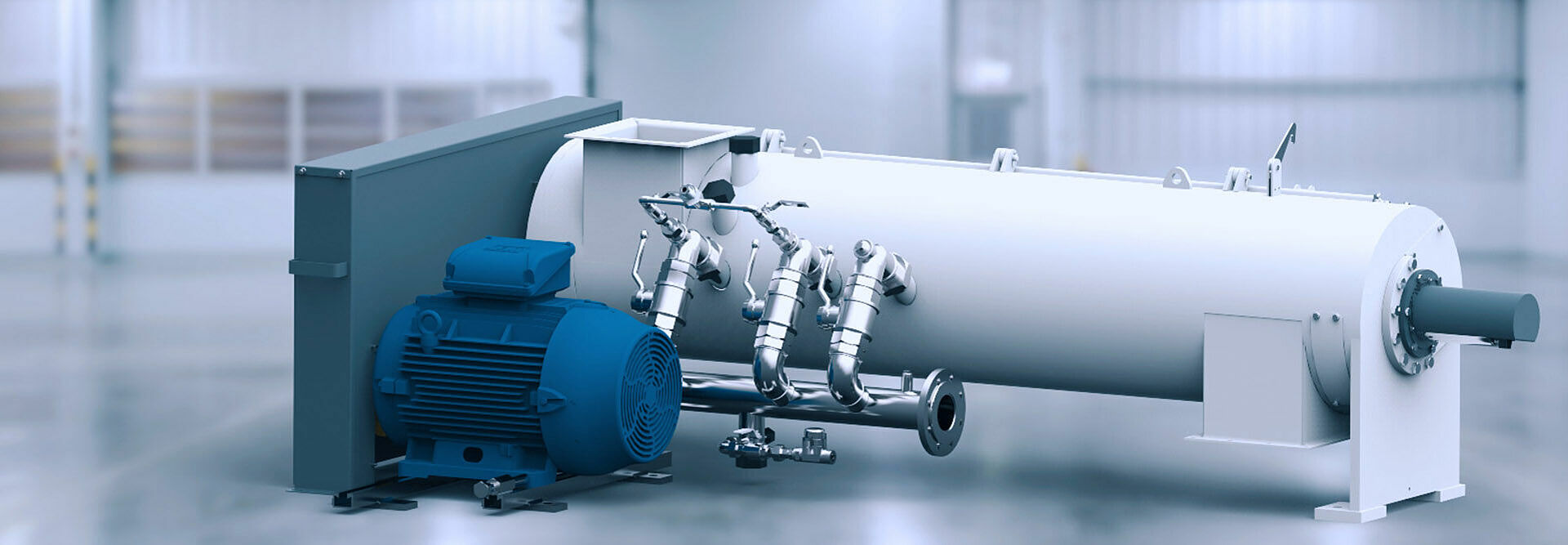

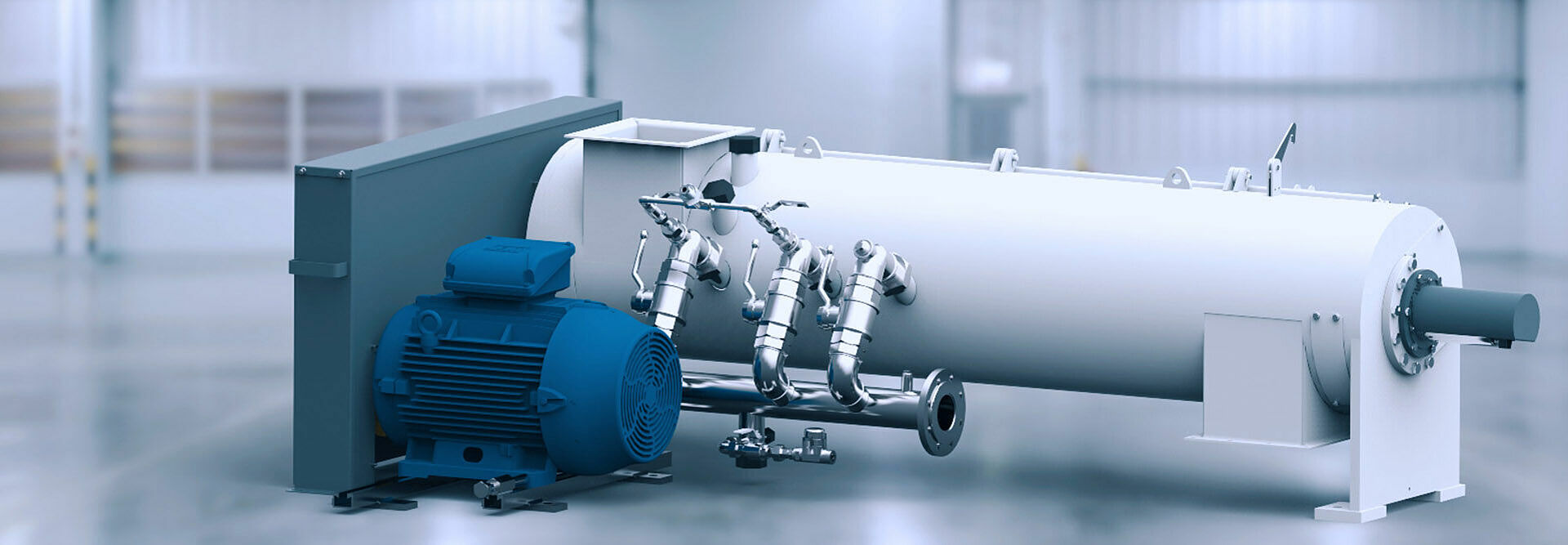

Our continuous mixer allows simultaneous addition of several bulk product flows, liquids and steam. Using the whirling principle, you can produce a lump-free mixture. The throughput time and the type of whirl formation can be influenced by adjusting the agitator blades. Thus the mixing effect can be adapted to the product. In addition, we manufacture the continuous mixer in four different sizes with a motor power from 7.5 to 110 kW, which provides a high variability in throughput time.

Design

The case of the continuous mixer consists of a welded construction and is provided with large inspection and assembly flaps. To avoid adhesions, the mixing chamber can be lined with plastic or stainless steel on request. The inner jacket can be replaced through the assembly flaps. The liquid is added via injection devices. A strong shaft carries the adjustable and easily replaceable mixing tools made of wear-resistant special cast iron. It runs in anti-friction bearings arranged outside the mixing chamber. The mixing shaft is dynamically balanced with balancing discs arranged in separate chambers, resulting in exceptionally smooth operation. Subsequent balancing is possible at any time and on site. In addition, the shaft is provided with special seals between the mixing and balancing chambers.

Application

In general, the KAHL continuous mixer is used for all mixing tasks where liquids have to be added to solids. In particular, however, the continuous mixer is used when granular or powdery substances have to be moistened. Apart from that, our continuous mixer is used for continuous mixing of feed with liquids and steam as well as for molassing of dried beet pulp.