Conditioning of fish feed, for example, is necessary to reach the best quality in terms of nutritional and physical properties. At the same time, the treatment serves as preparation for the subsequent (extrusion) process.

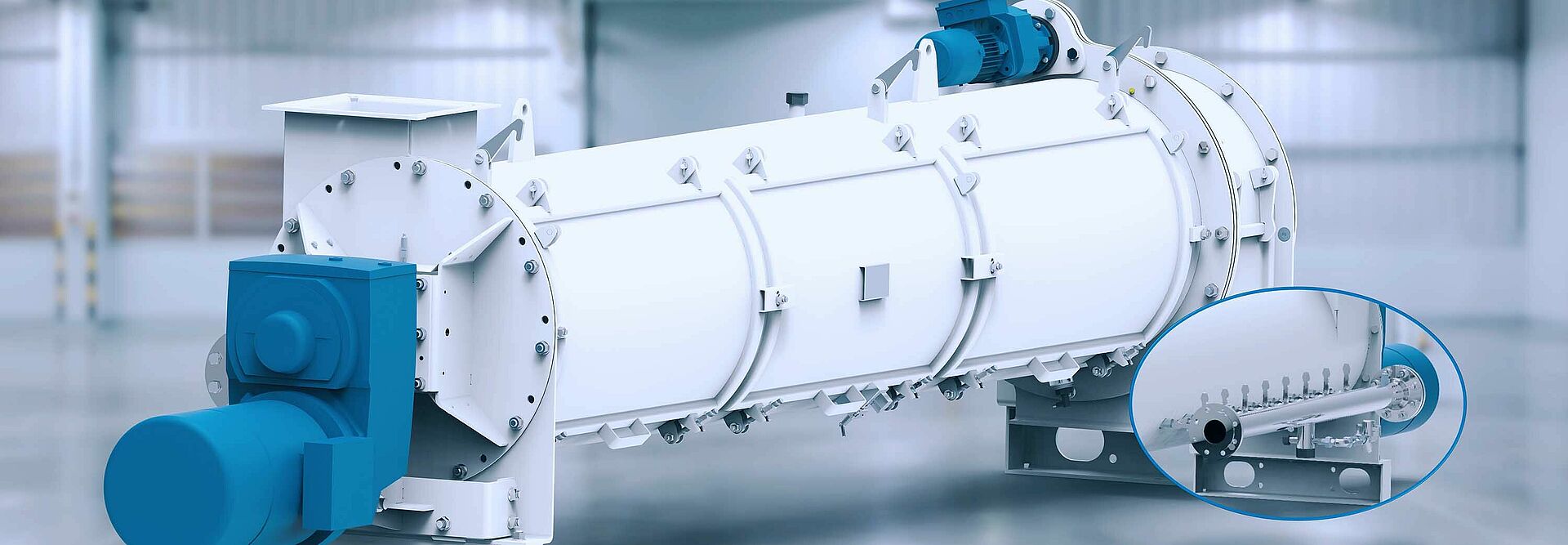

The retention conditioner VK is ideal for effective and economical mixing and heat treatment of feed and other demanding products. During conditioning, both steam and small liquid quantities can be added to the input product with firmly defined ratio of retention time and throughput. A precisely defined degree of filling provides the best results with regard to adsorption and absorption of the additives. Optimum product treatment is thus achieved, with exact adherence to operating parameters such as temperature and water content.

The special design of the continuously and electrically adjustable weir allows high filling levels and a long retention time and is therefore ideal for components that require longer heat treatment. The steam absorption is perfected by piling up the product. The shaft, case and mixing tools are made of stainless steel and are therefore optimal for long-lasting and gentle product treatment. As an option, all areas in contact with the product can be made of food grade materials.

Applications and Advantages

- Selectable useful volume for optimised throughput (2 sizes)

- Stainless steel design of all components in contact with the product

- Electrically adjustable weir for continuous adjustment of filling level and retention time

- Adjustable mixing tools to define retention time and mixing effect

- Surface temperature sensor for measuring the product temperature

- Large inspection openings for easy cleaning

- Drive via slip-on geared motor

- Suitable for meal feed or for conditioning upstream of extrusion

- High degree of hygiene due to minimized dead spaces in the machine/apparatus