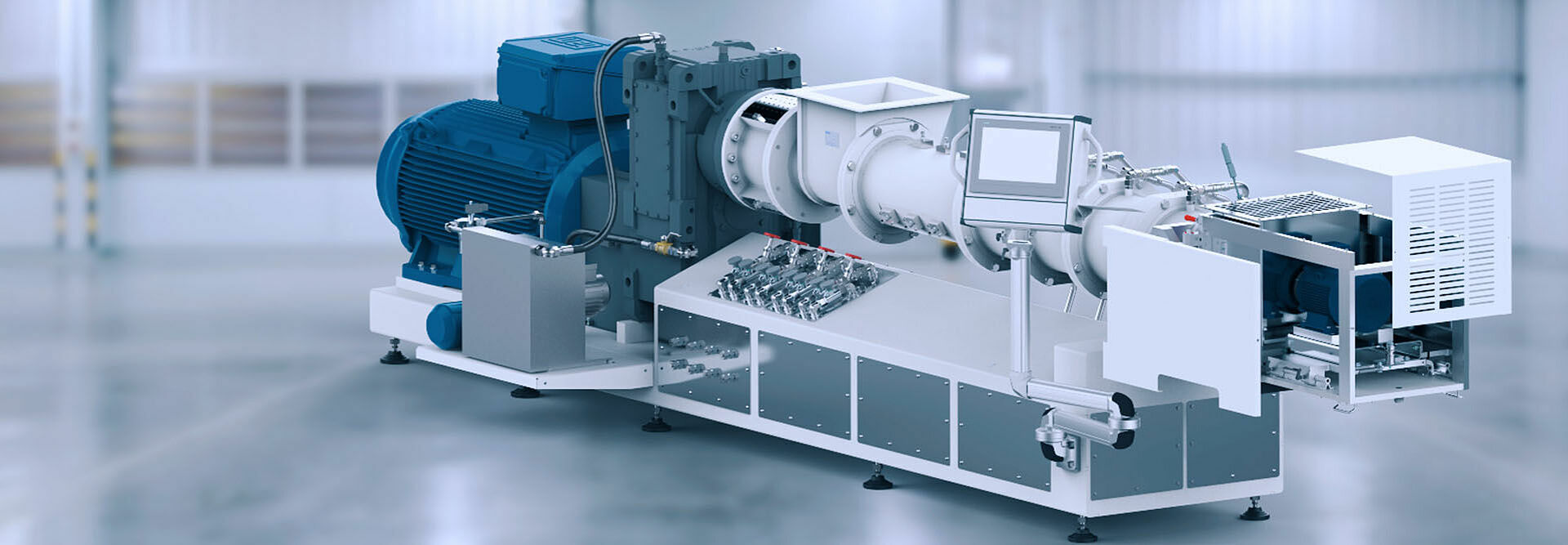

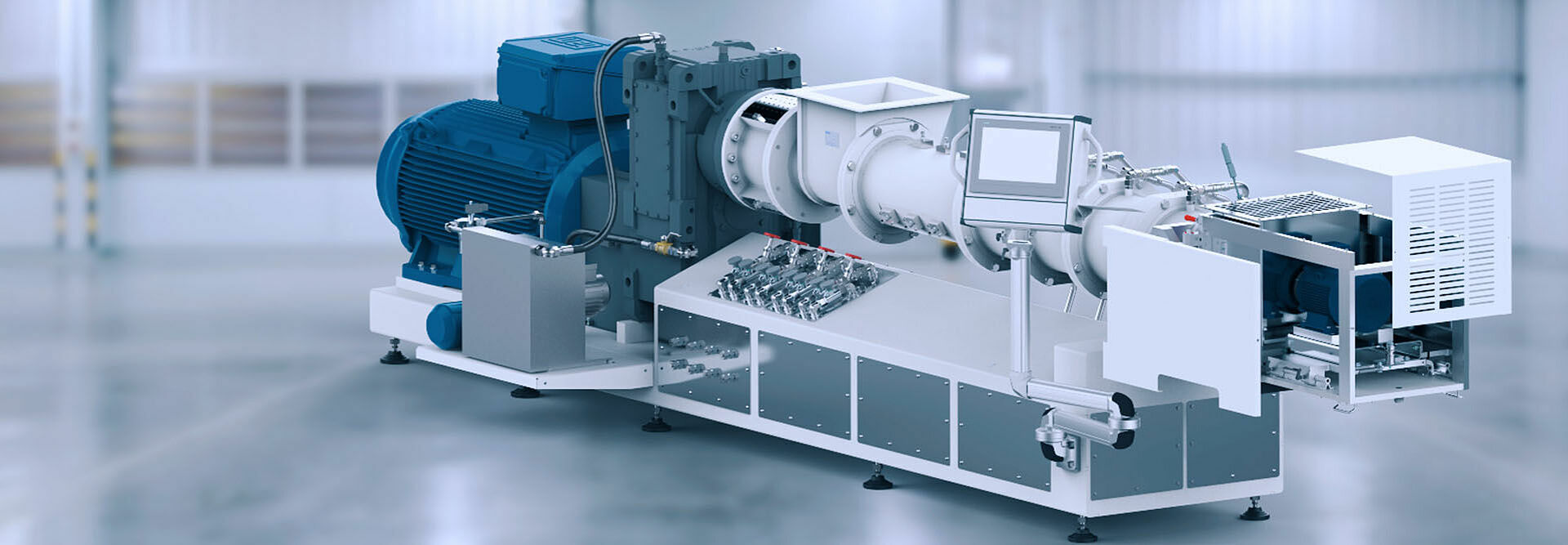

After more than 20 years of experience with extrusion systems, AMANDUS KAHL has developed the extruder OEE 25 NG to meet the increasing demands of the fast growing fish and animal feed markets. The new extruder features AMANDUS KAHL stop bolt technology for ideal mixing and venting in the first cylinder section. Special process sections for compaction, cooking and kneading provide a high degree of flexibility and a wide range of setting options for processing feed. Exchangeable screw elements ensure perfect adaptation to different recipes and quality parameters.

These features of our extruder are complemented by very effective fine-control measures, such as screw speed adjustment, steam/water addition to the extruder barrel and individually controllable heating/cooling jackets - all adjustable during operation for direct product quality response.

During the design process of the extruder OEE 25 NG, our engineers focused on developing a user-friendly machine. This is ensured by a double-joint connection, which enables fast tool and knife changes. The frame-mounted touch panel complements the user-friendly design and provides access to all relevant operating data, settings and options during commissioning and operation of the extruder in the compound feed sector.

Applications and Advantages of the Extruder

- Fast knife and die change

- Distance between knife and die adjustable during operation

- The new product family of the extruder comprises four different machine sizes

- All sizes are available as individual machines or turnkey extrusion lines and include all process steps such as grinding and mixing, steam conditioning, extrusion, drying, coating, cooling and packaging.

- The combination of individually adjustable screw elements and fine control measures makes it possible to meet the various requirements of our customers

- No complex and expensive additional equipment is required for the extruder to influence the expansion behaviour. This allows our customers to save both investment and operating costs.

- User-friendly machine

Manufacturer of Extruders for Industrial Applications

As one of the leading suppliers of pellet mills and pelleting plants for various industries, AMANDUS KAHL is committed to highest quality and state-of-the-art process technology. As a manufacturer of extruders for the compound feed industry, we not only cover the planning of the complete line, but are also available for consultation and intensive training of the operators. In addition, we at KAHL also supply spare parts and are therefore your partner far beyond the purchasing process.

Extruders for the Compound Feed Industry

One of AMANDUS KAHL's core competences is the manufacture of plants for the compound feed industry, where our extruder is used in particular.