Vacuum coating is a standard process in fish feed production. Depending on the feed type, 4 to 40 % oil are subsequently applied to the extruded fish feed. As this process results in excellent product quality, the vacuum coater is also used in the production of dog and cat food. The process is also increasingly being used in the field of compound feed production, particularly poultry feed. The subsequent addition of fat significantly increases the energy content of the feed, allowing high-fat compound feed components to be minimized in the formulae. This reduces the costs for the raw materials. Low-fat feed pellets often have significantly better qualities (e.g. abrasion resistance).

After the production of feed extrudates, pellets or porous products, the KAHL vacuum coater enables the refinement of the product with liquids. The product is sprayed with fat/liquid during the vacuum. Then the vacuum breaks and the liquid is forced into the interior of the product. In this way, almost all pores can be filled with liquid.

In addition, the subsequent application of several liquids is also possible. This has the advantage that the first liquid is inside the product and is surrounded by the second liquid in the pellet. Thus, sensitive additives can be protected, for example, or their taste can be masked. Since the vacuum coating process is carried out after the actual manufacture of the product, the defined addition of heat-sensitive additives is no problem. Extrudates with a larger pore volume absorb more liquid than comparatively dense pellets.

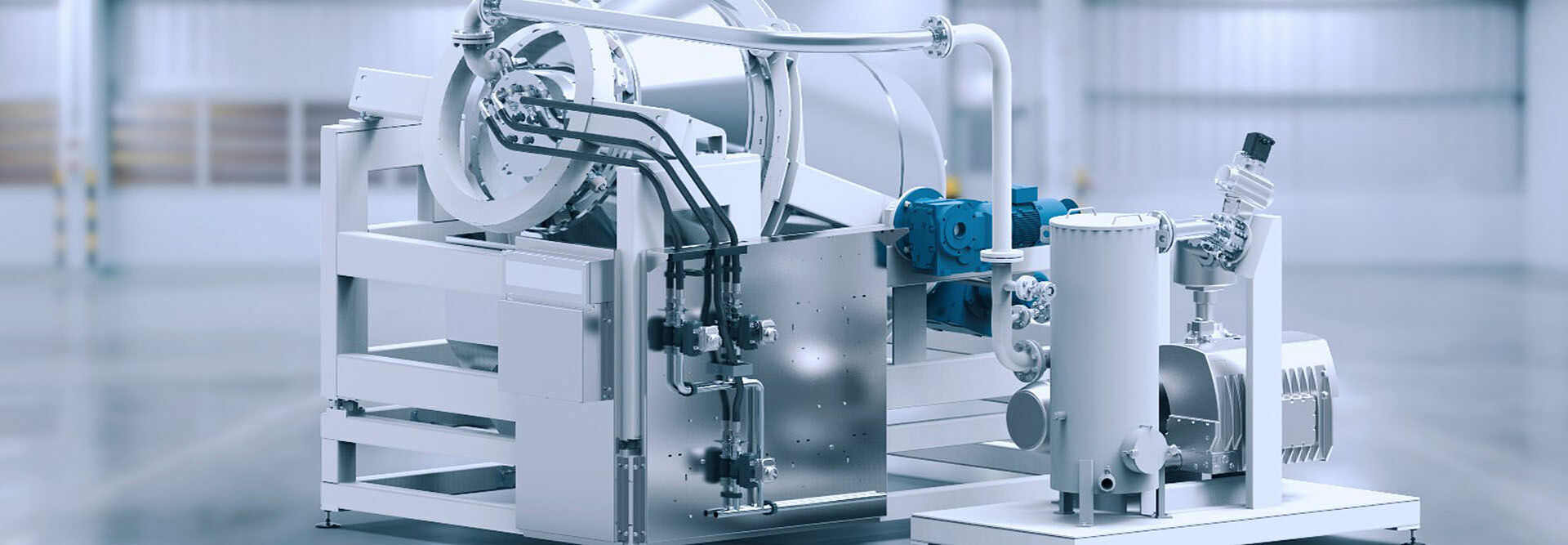

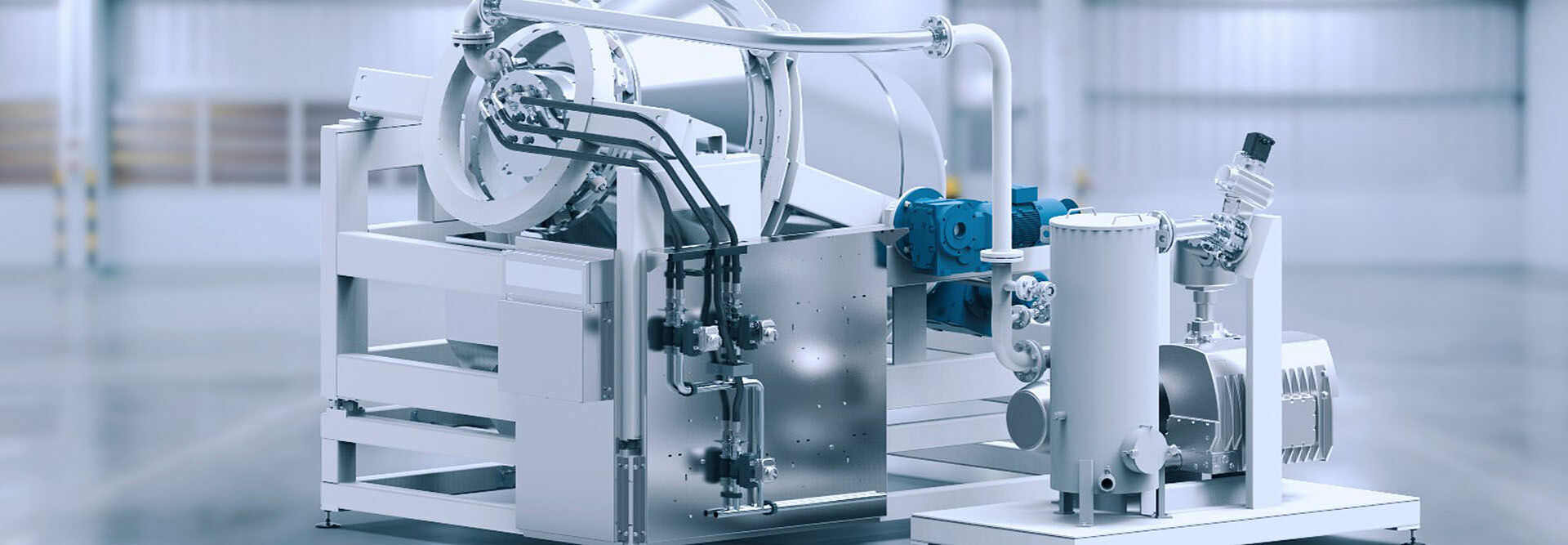

Due to the compact design of the coater, subsequent integration into existing systems is no challenge.

Process sequence

First, the drum is filled with the product to be processed. Weighing and proportioning are carried out by high-precision load cells integrated in the vacuum coater. Then the drum swings into working position, where the vacuum is generated. Now one or more liquids are sprayed one after the other onto the product. Afterwards, the vacuum is broken in a defined way. The drum is emptied by a pivoting movement downwards which ensures complete emptying. For cleaning and inspection, the drum can be completely pivoted toward the rear side, so that the best possible access is given.