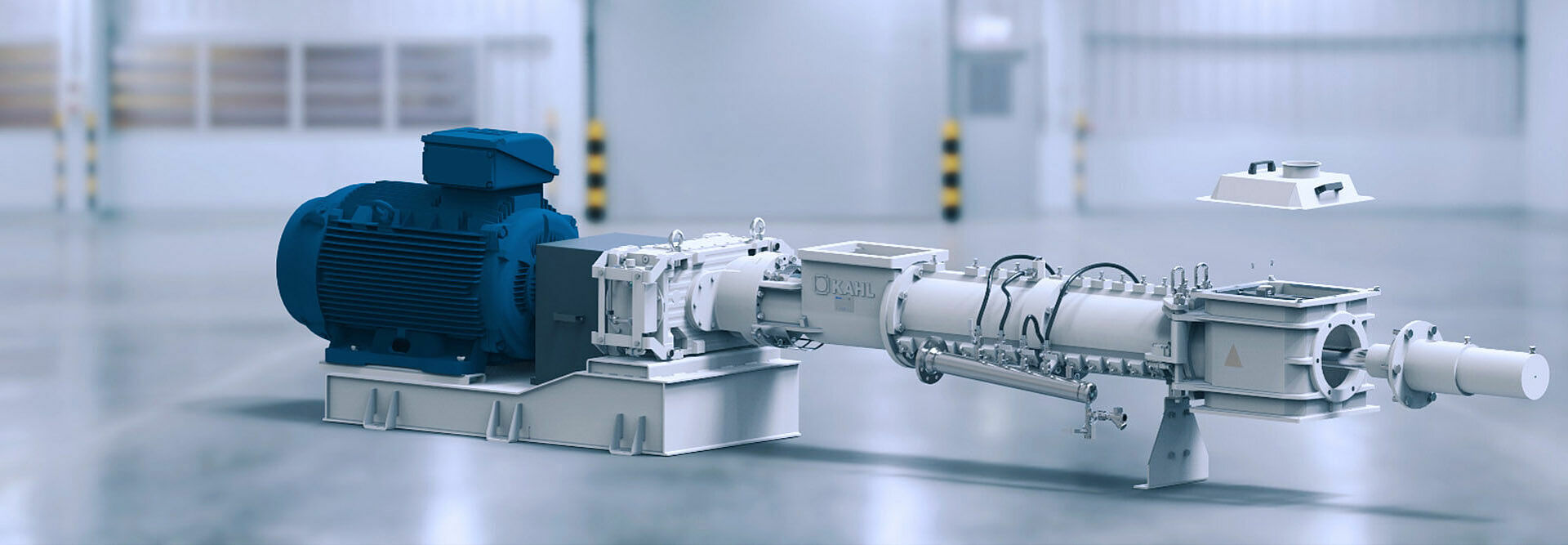

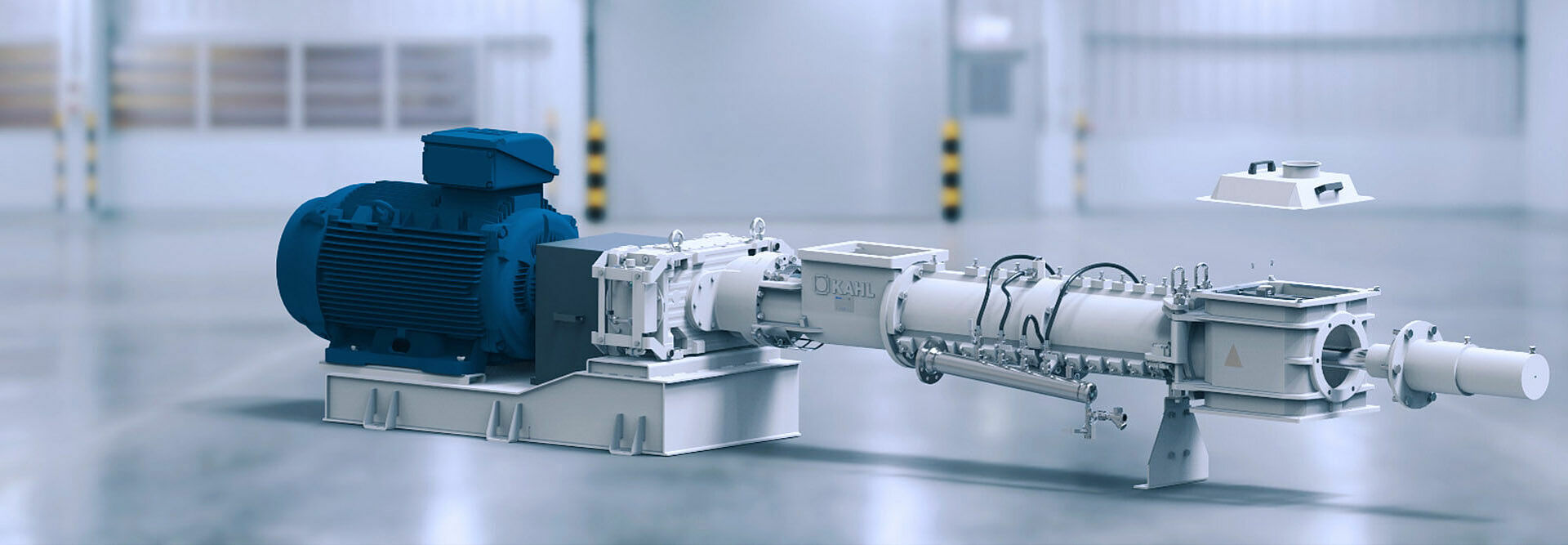

The hydraulically adjustable cone at the outlet together with the outlet ring form the patented annular gap. By adjusting the cone during operation, pressure, kneading intensity, product heating and energy consumption can be controlled and programmed continuously and without delay.

The maximum pressure is about 40 bar; the operating temperatures at the expander outlet are between 90 and 140 °C. At the outlet, the pressure drops spontaneously, the product expands, and a part of the added water evaporates (flash evaporation). Post-drying is not required. The particle size of the expanded product can be determined by means of the downstream crushing device.

Interested parties and customers can test the annular gap expander with their own mixtures in our pilot plant in Reinbek/Hamburg.

Our cooperation network goes far beyond machine and plant construction. We have invested considerable research effort in the development of the expander technology and have achieved optimum research results for almost every animal species, both under animal nutrition and economic aspects. Our network includes customer and industrial research as well as our own laboratory and pilot plant, research institutes, universities and independent consultants.

Applications and Advantages

- Liquids, such as fat, molasses, vinasse and fish solubles, can be added to the expander in larger quantities

- Expanded mixtures increase the press capacity

- Pellet hardness and fines can be influenced by changing the parameters

- On account of the precisely controllable process, value-determining ingredients are not damaged

- Pathogenic germs, such as salmonellae or moulds, are eliminated by the treatment in the annular gap expander