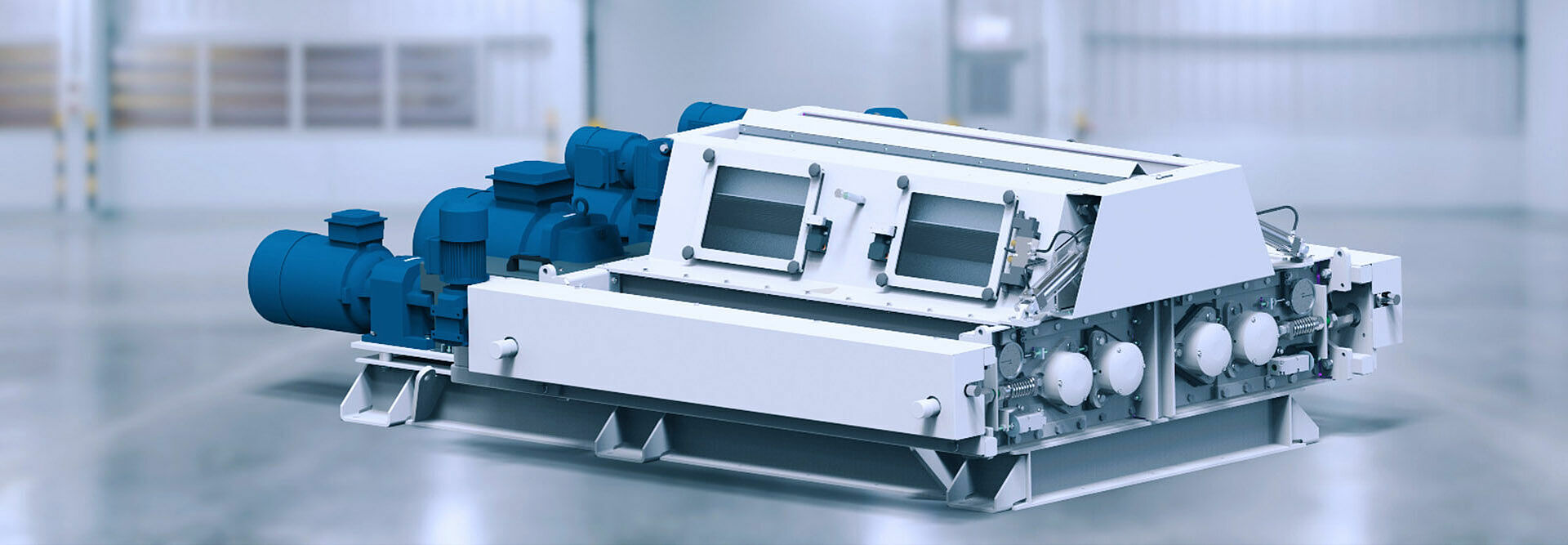

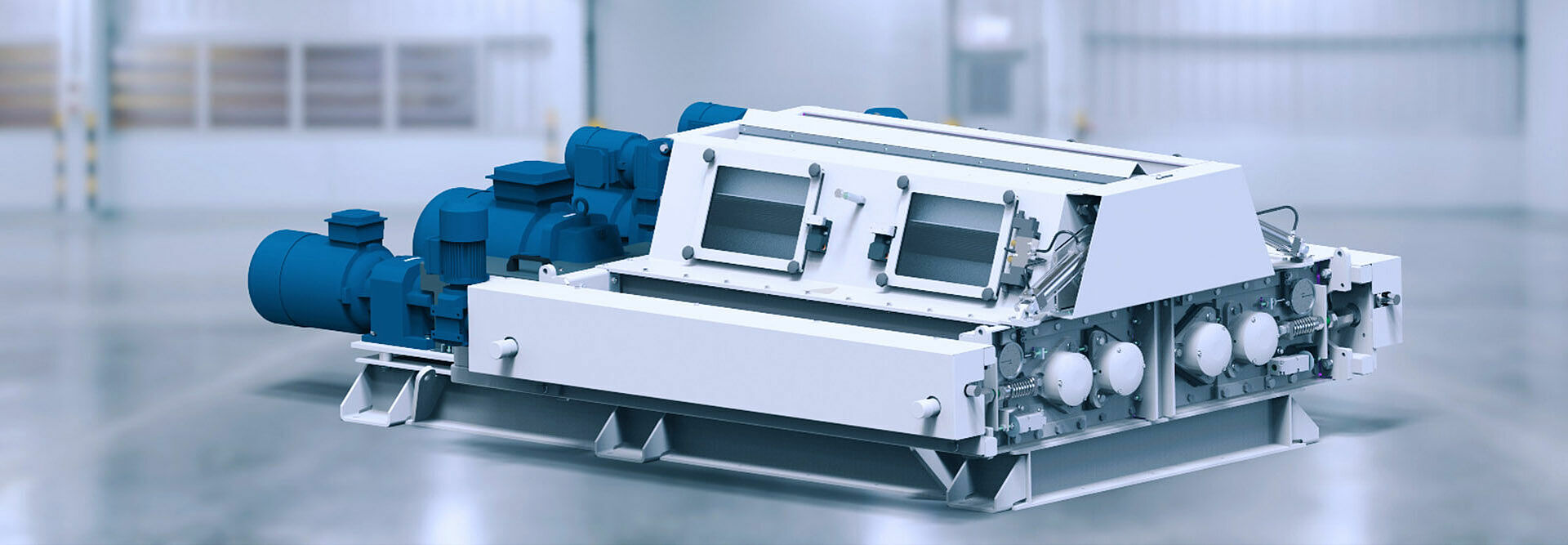

KAHL crumblers are used for crushing pellets or coarse-grained products in the animal feed industry - more precisely in the compound feed industry. The finished product is broken or crumbled. Crumbling is carried out by corrugated rollers and different rotating speeds. This results in only a small amount of fines, which can be returned to the press after screening. In addition, the particle size range can be influenced by changing the spring preload.

The rollers of the crumbler are mounted in a flat base frame. This not only enables problem-free installation in existing plants, but also the extension to a double crumbler.

The pellets are fed into the crumbler via the cooler discharge device or an additional feeding device. The optional feeding devices are equipped with a directly driven feed roller and an adjustable feeding flap. The drive does not differ from that of the crumbler - it is also arranged either on the left or on the right.

Design

- Roller removal both to the front and to the side possible

- Smooth operation, low wear and easy maintenance due to direct drive without chains, belts or gear wheels

- One roller is spring-mounted

- Roller gap and spring preload can be adjusted by means of screw spindles

- The gap width can be read on both sides at the dial gauges

- Additional remote control of the roller gap as well as the reversing flap settings by additional devices