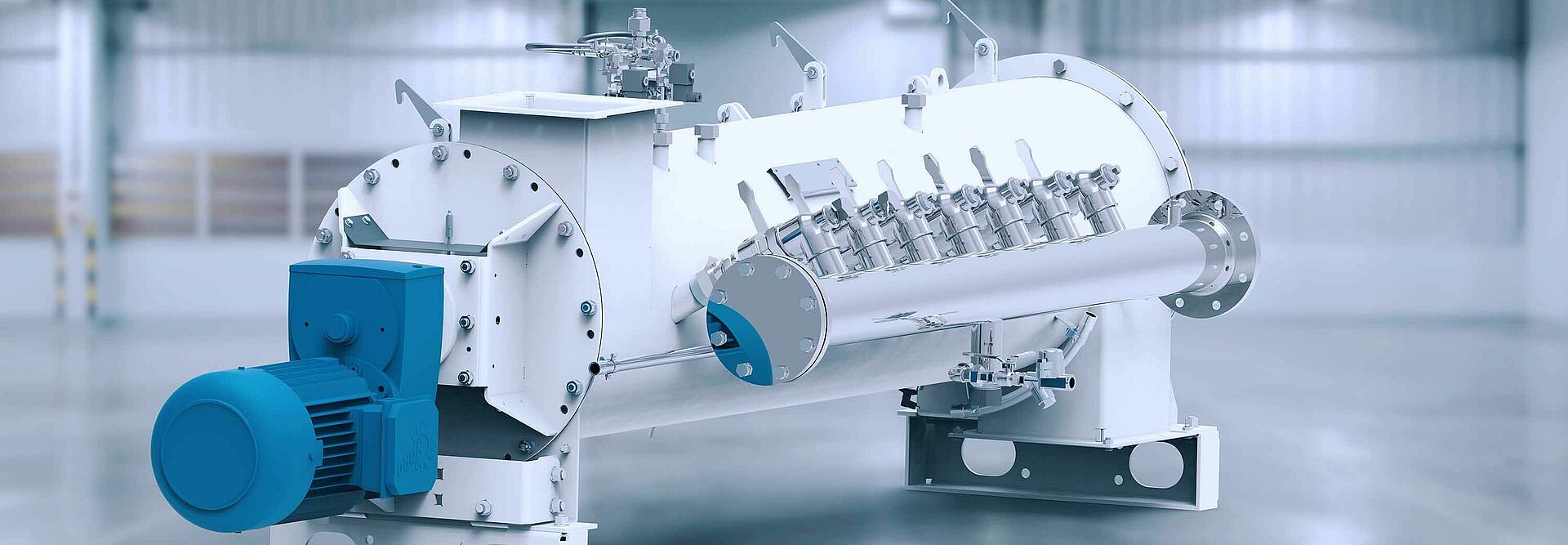

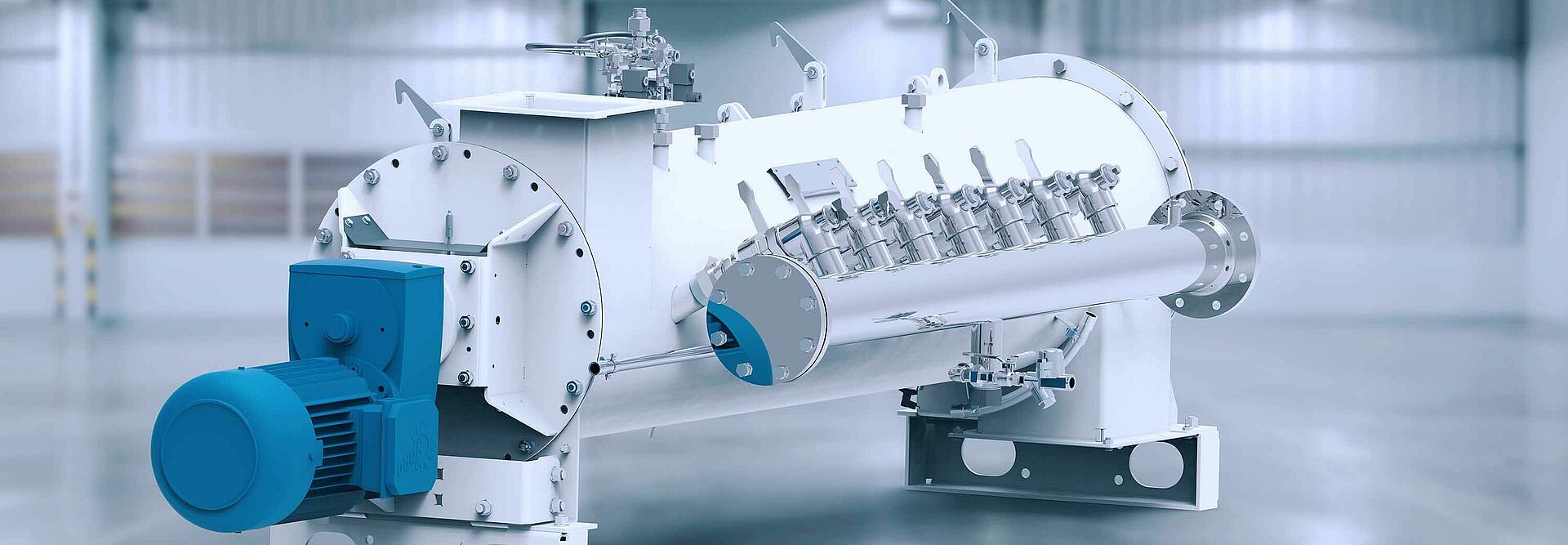

Conditioning of feed is necessary to ensure the best quality in terms of nutritional properties. At the same time, the treatment serves as preparation for subsequent process steps such as pelleting. The mixing conditioner is ideal for an effective and economic mixing and heat treatment of feed. During conditioning, steam as well as water and other partly highly viscous liquids can be added to the input product with firmly defined ratio of retention time and throughput. A precisely defined degree of filling provides the best results with regard to adsorption and absorption of the additives. Optimum product treatment is thus achieved, with exact adherence to operating parameters such as temperature and water content. As a result, in addition to feed conditioning, the use of the mixing conditioner is also ideal for the treatment of wood products. The shaft, case and mixing tools are made of stainless steel - for a long life and gentle product treatment. As an option, all components in contact with the product can be made of food grade materials.

Applications and Advantages

- Large volume

- Case in stainless steel design

- Adjustable paddles to influence the retention time, the filling degree and the mixing effect

- Surface temperature sensor for measuring the product temperature

- Large inspection openings for easy cleaning

- Drive via slip-on gear

- Appropriate for the treatment of mash feed or as conditioner upstream of the pelleting press